Troubleshooting Manual For Motor Rewinding

Related Electrical Products. The Motor Troubleshooting Learning System (85-MT2E), used in conjunction with Basic Electrical Machines (85-MT2), covers AC and DC motors troubleshooting and testing using a multimeter and a megger meter. The skills and knowledge covered by this system will prove invaluable for industrial maintenance technicians or anyone working in a field that uses AC and/or DC motors. This system covers major topics like AC and DC motor failures, common methods of diagnosing these failures by using a multimeter and megger meter, and troubleshooting these failures.

Motor troubleshooting includes a motor connection box to practice hands-on skills such as troubleshooting faults in a DC motor and AC single-phase and three-phase motors, evaluating DC electric motor commutator and brush health, and using a multimeter to test an AC motor start/run capacitor. Amatrol’s industrial training systems feature real-world, industry-grade components for durability that will stand up to frequent use and to allow learners to gain real-world competencies. This system requires Basic Electrical Machines (85-MT2), a digital multimeter, and a megger meter.

Hands-On Motor Troubleshooting Skills with Real-World Applications Motor troubleshooting features a motor connection box that, when used in conjunction with the Basic Electrical Machines, a multimeter, and megger meter, allows learners to practice hands-on motor troubleshooting skills. This learning system covers a wide variety of areas where failures can occur within AC motors (bearing failure, start windings, centrifugal switch, thermal switch) and DC motors (couplings, brushes, armature, field winding, and power supply). This array of topics allows learners to gain confidence and competence when practicing applicable hands-on skills and to see how they translate to real-world situations. Comprehensive Knowledge on How to Test, Diagnose, and Troubleshoot AC and DC Motors This industrial motor training system’s curriculum begins by explaining common types of AC and DC motor failures and causes and builds by allowing learners to study how to test, diagnose, and troubleshoot these problems. Specific objectives include listing common failures of a three-phase AC motor’s stator windings, understanding common methods used to diagnose DC motor failures, and using a megger meter to test a DC electric motor armature.

The included curriculum is interactive multimedia that can be used for classroom teaching or self-paced learning. This multimedia features stunning 3D graphics and videos, voiceovers of the text, and interactive quizzes and exercises. Additional Electrical Motor Training Motor troubleshooting is just one option for electrical motor training from Amatrol. Other options to add onto Basic Electrical Machines include DC Generators (85-MT2B), Alternators / Synchronous Motors (85-MT2C), and Wound Rotor Motor (85-MT2D).

A single phased winding failure is the result of an open/cut in one of the phases that supply power to the motor. The open/cut is usually caused by a bad.

DC Generators features resistive and inductive load units to teach the operation, installation, and selection of DC generators for various applications. Alternators / Synchronous Motors includes capacitive load, combination synchronous motor/ alternator, and synchronizing lights / switch unit to cover topics like alternator output voltage and frequency, three dark synchronization method, and reversing a synchronous motor. Wound Rotor Motor includes a wound rotor controller and motor to cover topics such as speed controllers, motor reversing, and performance analysis and measurement. Student Reference Guide A sample copy of the Motor Troubleshooting Student Reference Guide is also included with the system for your evaluation. Sourced from the system’s curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfectly-bound book. Student Reference Guides supplement this course by providing a condensed, inexpensive reference tool that learners will find invaluable once they finish their training making it the perfect course takeaway.

When troubleshooting a faulty electric motor, time (or in this case downtime) is money. This notion was drilled into my head in my early years and has proven itself over and over again. Isolating the problem in the shortest amount of time saves costly downtime (and maybe even your job). The other point that has been permanently burned into my consciousness involves a different type of self-preservation: always control the electrical circuit you are troubleshooting by following proper lock-out/tag-out procedures. Observing safe maintenance procedures must always be given proper attention. For these reasons, it is imperative that the maintenance electrician, technician or engineer uses a troubleshooting methodology that enables them to isolate the problem in the shortest amount of time. Still, the logical process of elimination used to identify the root cause of an ac motor's malfunctioning can differ.

Troubleshooting Manual For Motor Rewinding Machine

At times it is more effective to start at the motor and work back to the starter; in other instances it's better to begin at the starter and move towards the motor. My general preference is to begin at the excitation source and work towards the motor. For the purpose of this article, I'm addressing typical starting problems only. Running problems can be numerous and varied, and in many cases can be traced all the way back to improper motor specification for a particular application. Starting problems with three-phase ac inductive motors can be grouped into three primary categories: voltage source problems; motor excitation problems, which include the motor starter and ac drive; and application or mechanical problems.

Troubleshooting voltage source problems Use a process of elimination to isolate and diagnose voltage source problems. Refer to 'Voltage source problems flowchart' on page 66, which illustrates the steps of the following troubleshooting procedure:. Check the incoming power to the motor starter. Using a digital multimeter (DMM) set to voltage mode, verify that all three phases of electrical potential are present. If one or more of the phases is missing, disconnect the primary voltage source (incoming power disconnect switch) and replace the incoming power fuses or reset the motor-control circuit breaker. Prior to restoring the primary voltage source, set the DMM to continuity mode (ohms) and verify at the motor starter line contactors that there is not a phase-to-phase short or a phase-to-ground short. If there is a short or ground on the line side of the starter, replace the starter contactor and verify that the short or ground is now clear.

Next, verify that the load side of the circuit does not have a phase-to-phase short or a phase-to-ground short. This final continuity check will also verify that the motor line does not have an open phase. If the motor starter line circuits are clear, the problem is on the load side of the starter. Follow the circuit to the load side of the starter. Try to reset each of the motor thermal overloads on the motor starter. If any one of the overloads have tripped you will be able to feel when the overload resets while pressing the reset pushbutton.

If you completed the continuity check of the load side of the motor contactor described in Step 2 and the circuits are clear, restore the incoming power and start the motor. If the continuity check on the load side of the contactor is shorted phase-to-phase, phase-to-ground or open phase-to-phase, then follow the power circuit to the motor. Disconnect the incoming motor leads at the ac motor electrical conduit box. Check the motor starter leads for a phase-to-phase or a phase-to-ground short. If either of these two problems exists, check the motor lead wiring. If the motor starter leads are clear, move on to the motor.

With the motor still disconnected, check the motor leads for a phase-to-phase or a phase-to-ground short. There is a high probability that if there were no problems found previously in the circuit, the motor has a phase-to-phase short or a short-to-ground fault. If you have verified a phase-to-phase or phase-to-ground fault in the motor, replace the motor and start the system. If there appears to be no problem with the ac motor or its power circuit, then test the motor insulation with an insulation tester. The insulation test determines if the motor windings are 'breaking down' during running conditions. If the insulation test results are negative, a mechanical problem is probably causing the motor overload. Uncouple the motor from the mechanical load and start the motor.

If the motor runs, the problem is in the mechanical drive train. If the motor does not run and the motor overloads trip again, the problem is in the motor bearings. Troubleshooting control circuit problems. You can also use a process of elimination to isolate and diagnose control circuit problems. Refer to 'Control circuit problems flowchart' on page 68, which illustrates the steps of the following troubleshooting procedure:. If all three phases of electrical voltage were present when you performed Step 1 of 'Troubleshooting voltage source problems,' then the motor starter overload and control circuits should be checked.

Determine if all or any of the motor starter overloads are tripped by pressing the motor overload reset pushbutton. If the motor overload(s) were tripped, try to restart the motor. If the problem was isolated to the motor overload(s), the motor should run. If the motor overload(s) trips again, return to Step 5 of 'Troubleshooting voltage source problems' to determine if the problem is a motor problem or load problem. If the motor overloads are not tripped, verify that the starter control circuit has the proper secondary voltage using a DMM set to voltage mode and the appropriate range.

If the proper voltage is not present, disconnect the motor starter's incoming power supply. Using the DMM in continuity mode (Ohms), verify the integrity of the control voltage transformer fuse. Replace the fuse if blown, and. identify the motor starter control circuit problem.

If the starter control transformer fuse is good, proceed to Step 8 of this troubleshooting procedure. Disconnect the motor starter contactor coil and check for a short, ground or open circuit. If a short or ground is found, replace the motor starter contactor coil and start the motor. If the motor start contactor coil is good, with the coil still disconnected, check the control circuit wiring to the contactor coil.

Small Electric Motor Rewinding Services

If a short or ground is detected, disconnect the field wiring circuit to the motor starter to determine if the problem is internal to the motor contactor overload circuit(s) or in the field control wiring. If an electrical ground is located in the motor starter overloads circuit, replace the motor overload(s). Once the failed motor overloads have been replaced verify circuit continuity, reconnect the starter coil and control field wiring, restore incoming power and start the motor. If an electrical ground is not located in the motor starter overload circuit, the problem has been isolated to the control circuit field wiring.

Clear the ground in the field wiring circuit. Then reconnect the motor starter coil, overload circuit and field wiring, restore incoming power and start the motor. If you determine that the starter control voltage is intact and present, suspect a potential open circuit in the motor overloads or control circuit. To check for an open circuit, first disconnect the incoming power supply, and using the DMM in continuity mode (Ohms), verify the circuit integrity of the motor overloads control circuit (secondary contacts). If the motor overloads control circuit is good (all NC contacts have continuity), then the field control circuit to the motor starter is the problem. To troubleshoot the field control circuit to the motor starter, check continuity across the device that supplies the start signal to the motor starter, which could be a PLC contact closure, relay contact closure or start/stop pushbutton circuit. After the control circuit problem has been located and corrected, restore the incoming power and start the motor.

AC drive excitation — drive faults. When a drive fault occurs in an ac drive and motor application, determine if the fault is a motor, drive or application problem. The diagnostic technology offered in modern ac drives can help you troubleshoot many drive problems. Manufacturers often include internal diagnostic capabilities in the drive's microprocessor control. By using these drive fault diagnostics, you can easily determine and remedy the fault.

Some of the most common problems related to integrating an ac drive with an ac motor are listed in the table 'Typical ac drive faults.' However, there are may other possible drive faults associated with motor/drive tuning, application requirements, communication errors, external device errors and initial programming errors.

If you are still unable to locate the source of the trouble after ruling out the causes listed in the table, contact the equipment manufacturer or your local distributor for further diagnostic assistance. The majority of ac motor and drive problems can be solved by using the drive manufacturer's manual. Each drive fault that is monitored and annunciated by the drive's microprocessor is listed in the troubleshooting section of the manual. If you cannot locate your manual, contact your local manufacturer's representative or refer to the manufacturer's website to download a copy. AC motor and drive technology The application of ac motor and ac drive technology is becoming much more prevalent in applications that were previously done with dc technology (variable speed applications) or across-the-line starters (historically constant speed applications used on fans and pumps). With the development of different ac drive technologies, such as soft start, V/Hz, open loop vector and closed loop vector drives, this trend will likely continue — and if anything, increase. The ability to apply the right ac motor technology in the right application ensures that the motor/excitation technology used will provide trouble-free operation for many years.

The ability to develop and execute a logical troubleshooting methodology when equipment failure does occur will assure that your process achieves the maximum amount of uptime. Annual Salary Survey After two years of economic concerns, manufacturing leaders once again have homed in on the single biggest issue facing their operations: It's the workers—or more specifically, the lack of workers. The 2017 Plant Engineering Salary Survey looks at not just what plant managers make, but what they think. As they look across their plants today, plant managers say they don’t have the operational depth to take on the new technologies and new challenges of global manufacturing.

1974 Harley Davidson Ironhead Service Manuals

This is an Original Service Manual in good used condition. Pages and binding are all in tact and in good shape.| eBay!

REMOVAL Prepare for Service 1. Position motorcycle on a suitable lift. NOTE If vehicle is equipped with Harley-Davidson Smart Security System, see owner’s manual for instructions to disarm the system. To prevent accidental vehicle start-up, which could cause death or serious injury, disconnect negative (-) battery cable before proceeding.

Disconnect battery cables, negative (-) battery cable first. Remove seat according to the instructions in the service manual. Refer to service manual to remove left saddlebag and side cover. When servicing the fuel system, do not smoke or allow open flame or sparks in the vicinity. Gasoline is extremely flammable and highly explosive, which could result in death or serious injury. Remove fuel tank according to the instructions in the service manual.

Remove Engine Components 1. Remove existing air cleaner assembly.

Discard backplate but save remaining parts. Refer to AIR CLEANER REMOVAL in service manual. Remove existing exhaust system. Refer to EXHAUST SYSTEM REMOVAL in service manual. Remove engine from chassis following the instructions in the service manual. Disassemble engine top end and bottom end.

Refer to appropriate ENGINE sections in service manual. Remove existing clutch diaphragm spring. Refer to CLUTCH REMOVAL in service manual.

The procedures in this instruction sheet should be performed by one experienced in precision measuring techniques. Failure to meet tolerances called for in this instruction sheet can result in engine damage. (00511b) -J04793 1 2 is03517 1. O-ring counterbore 2.

Spigot bore Figure 1. Spigot Bore and O-Ring Counterbore Dimensions Table 1. Spigot Bore and O-Ring Counterbore Dimensions Depth Bore Description 1.625 +/- 0.010 in. (41.3 +/- 0.25 mm) 4.205 +/- 0.010 in. (107 +/- 0.25 mm) Spigot Bore 0.085 +/- 0.003 in. (2.16 +/- 0.08 mm) 4.415 +/- 0.002 in.

(112 +/- 0.05 mm) O-Ring Counter- bore is03456 Figure 2. Cylinder Wall MACHINE CRANKCASE Crankcase Boring Preparation NOTE During final assembly of the engine, Harley-Davidson recommends replacing the OE cylinder studs with Screamin’ Eagle High Tensile Studs (16505-01). Remove cylinder studs from the engine crankcase. Mask off all bearings and oil holes to prevent debris and contaminants from entering those areas.

1972 Harley Davidson Shovelhead

Inspect and clean engine case mating surfaces. See Figure 6. Reassemble engine case with OE screws, except the top center screw between the cylinders, and tighten to specifications listed in service manual. NOTE To prevent damage to crankcase boring tool, it is important to replace the top center screw with a modified top center screw (1093). This screw is included in the Crankcase Boring Tool Kit (94419-06) and can be purchased separately from a Harley- Davidson dealer. Install modified top center screw (1093) between the cylinders and tighten to 50-90 in-lbs (5.6-10.2 Nm).

1974 Harley Davidson Ironhead

See Figure 1 and Table 1. Machine crankcase cylinder spigot bore and O-ring counterbore to the dimensions shown. Modify Crankcase Incoming search terms:.

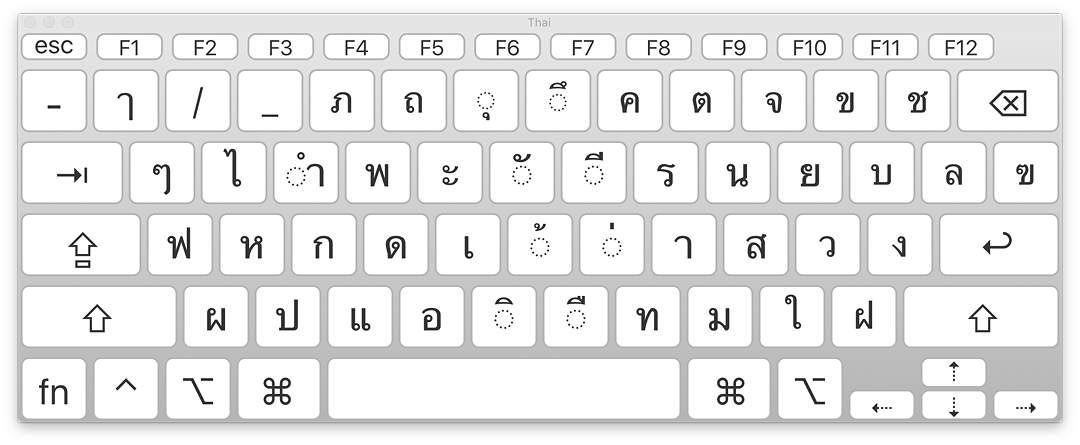

Thai Keyboard For Mac

Read reviews, compare customer ratings, see screenshots, and learn more about My Thai Keyboard. Download My Thai Keyboard and enjoy it on your iPhone,.

Windows XP operating system: Click START, open CONTROL PANEL. Select REGIONAL AND LANGUAGE OPTIONS. Click on LANGUAGE tab, then DETAILS and SETTINGS tab. Click ADD and then select THAI from the drop down INPUT LANGUAGE box and THAI KEDMANEE from the drop down KEYBOARD LAYOUT box. Click OKAY, OKAY, APPLY, OKAY. Thai language should then be installed. One possible problem is that files for complex scripts may not have been installed, If so, then on Windows XP, as an administrator: Click START, open CONTROL PANEL.

Select REGIONAL AND LANGUAGE OPTIONS. Click on LANGUAGE tab, tick 'Install files for complex script.' And click OK etc.

If this doesn't work, there are various web pages you can use, e.g. It enables you to switch input methods, so it may be sensitive to browser differences. (I've just discovered that it gets a bit sick on Mozilla if you switch the encoding away from 'Unicode (UTF-8)', which is the encoding declared on the page. IE6 doesn't seem to be affected by such a switch.) As to fonts, you just drag the font file onto the fonts directory, e.g.

C: WINDOWS FONTS. The consonants, subscript vowels, superscript tones and over marks in the vertical stack are typed in the order: 1) Consonant first. 2) Everything else in order from bottom to top, so tone marks come last. Preposed vowels (เ แ ไ ใ โ) and postposed vowels (า ำ ะ) are typed independently, as though they were consonants. Note that น้ำ is typed in the order: consonant, tonemark, vowel. Do not type ำ as two symbols - if you do, most search software will not equate it to ำ as a single symbol.

On Thaivisa, remember to make Thai text 'large' (I use size 7) to make it legible. On a Mac with OS/X: Apple Menu - System Preferences - 'International' Preference Pane - Input Menu Click on 'Thai' check box Click on 'Show input menu in menu bar' Quit System Preferences The input menu will appear in the menu bar at the far right. It is represented by the flag of the country of the current input language. (US flag for US English, British flag for real English, Thai flag for.) Click on the flag and select the language of choice.

If you need help with the keyboard, click on the flag and select 'Show Keyboard Viewer'. You can use the Keyboard Viewer for actual input or just as a map. For the Mac Safari web browser you have to set the Text Encoding method to Unicode or Thai: View - Text Encoding - Unicode or View - Text Encoding - Thai - Thanks to Richard W for the WinXP instructions and mgnewman for the Mac/OSX instructions.

As more information is found, these instructions will be updated. Edited February 13, 2005 by RDN. RDN; Without trying to sound like a total pratt, Having a keyboard with the Thai Key-tops helps as well.

You can buy them very cheaply at most computer shops, then you don't have to use the stickers if your keyboard only has the 'western' Keytops. RDN Edit: For sure a Thai keyboard is easy to get and install, but I think you meant to post this on the original thread?

Anyway, I too have a USB Thai keyboard - 'Genius brand, model KU-0138'. But I also have an external hard drive connected to my lap-top's only USB port, and it doesn't work too well sharing the port with another device. Hence, in the other topic, I talked about the 'On-Screen Keyboard'. For short periods, it's OK - you just see a normal keyboard until you switch language using the Language Bar. Then the keys change to the Kedmanee keyboard and - using the mouse - you can type in Thai.

But if I want to do a lot of typing, I will plug in the USB keyboard. I will add information later about keyboards to the pinned first post above.

Download Thai Keyboard

Edited February 13, 2005 by RDN. I had the same problem. My missus wanted to make up a rough draft on word for our wedding invitations. All well and good in English. But just couldn't get the Thai to work.

Even by changing the settings said before. Then by pure accident i clicked on the EN sign at the bottom right hand corner. This gave me the option to change to Thai. And hey presto it worked. So i got brownie points for that.

Since the missus was getting a little pissed off. Now shes as happy as a pig in. The small things that make our life easy. I noticed this a while ago - I think I posted a message about it in another thread.

Thai Keyboard Stickers Mac

I usually click in an 'edit' box in this forum web or in 'Notepad' before attempting to change the input language. Have you read the topic about the 'Microsoft Visual Keyboard'. You can get it from here: I use it now in preference to the 'on-screen keyboard' that comes with XP as it can be made large and so is much easier to read - especially the Thai fonts on the keys. This program was actually written for operating systems other than XP because they did not have an 'on-screen keyboard'. But the guys who wrote this program obviously learned about some of the failings of the 'on-screen keyboard' and made it better! I can produce ๆไไำพะััีรรนรย., as though some one were just tapping keys from left to right along the second row and producing an arbitrary string of Thai characters. The problem seems to be that your browser thinks it is reasonable to send the text you entered in the encoding of the page, so it sends 8-bit codes.

At the receiving end, the server is probably expecting Latin-1, so that is how they are interpreted. Mishap - your message can then only be read if the Thaivisa page is switched to a Thai encoding. With IE or Firefox on Windows XP, I just leave the encoding unchanged and type with the keyboard set to Thai or English as I desire, and it works fine. Cutting and pasting to here from other web pages in a Thai encoding also work fine. The same goes for Windows 2000 and IE, except I don't have the facility to type in Thai on that Windows 2000 system - I have to type the Thai in a special program and then cut and paste.

As you type the message into the editing box, it should be stored as 16-bit Unicode codes. I recommend that you try to type in Thai without changing the encoding of the web page - leave it as Latin-1/Western European.

When i opened a word document and typed i just got a series of blank squares for every character typed. Is there something i have done wrong? If you are using Word X, it is obsolete and can't do Unicode scripts like Thai. Aside from AppleWorks, any other word processor should work ok. If you are using Word 2004 and higher, make sure you have it set to a font that includes Thai, like Lucida Grande, Thonburi, Ayuthaya, Silom, Krungthep. Even so, MS products do not support correct Thai linebreaking, so best to use an Apple app like TextEdit or Pages, which does. When i opened a word document and typed i just got a series of blank squares for every character typed.

Is there something i have done wrong? If you are using Word X, it is obsolete and can't do Unicode scripts like Thai. Aside from AppleWorks, any other word processor should work ok. If you are using Word 2004 and higher, make sure you have it set to a font that includes Thai, like Lucida Grande, Thonburi, Ayuthaya, Silom, Krungthep.

Even so, MS products do not support correct Thai linebreaking, so best to use an Apple app like TextEdit or Pages, which does. Apple Footer. This site contains user submitted content, comments and opinions and is for informational purposes only.

Apple may provide or recommend responses as a possible solution based on the information provided; every potential issue may involve several factors not detailed in the conversations captured in an electronic forum and Apple can therefore provide no guarantee as to the efficacy of any proposed solutions on the community forums. Apple disclaims any and all liability for the acts, omissions and conduct of any third parties in connection with or related to your use of the site. All postings and use of the content on this site are subject to the.

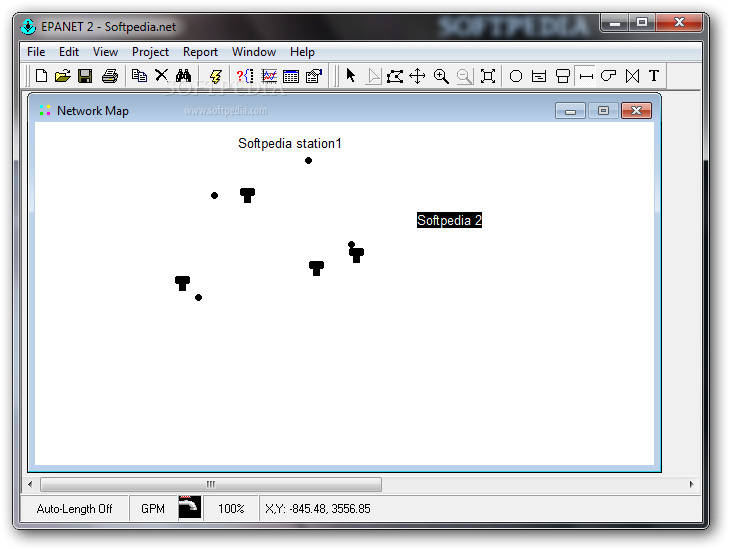

Epanet Software For Mac

US EPA EPANET Introduction EPANET is a Windows 95/98/NT program that performs extended period simulation of hydraulic and water-quality behavior within pressurized pipe networks. A network can consist of pipes, nodes (pipe junctions), pumps, valves and storage tanks or reservoirs. EPANET tracks the flow of water in each pipe, the pressure at each node, the height of water in each tank, and the concentration of a chemical species throughout the network during a simulation period comprised of multiple time steps. In addition to chemical species, water age and source tracing can also be simulated.

EPANET was developed by the Water Supply and Water Resources Division (formerly the Drinking Water Research Division) of the U.S. Environmental Protection Agency's National Risk Management Research Laboratory. It is public domain software that may be freely copied and distributed. EPANET provides a fully-equipped, extended period hydraulic analysis package which can:. handle systems of any size. compute friction head loss using the Hazen-Williams, Darcy-Weisbach, or Chezy-Manning formulas. include minor head losses for bends, fittings, etc.

EPA SWMM 5 for Mac OS X. The EPA SWMM (Storm Water Management Model) is an app that can be used to design and analyse sewage networks. EPA provides a Windows version of the program as well as the source code.

Epanet Software For Mac Download

model constant or variable speed pumps. compute pumping energy and cost. model various types of valves including shutoff, check, pressure regulating, and flow control valves.

allow storage tanks to have any shape (i.e., diameter can vary with height). consider multiple demand categories at nodes, each with its own pattern of time variation. model pressure-dependent flow issuing from emitters (sprinkler heads).

base system operation on simple tank level or timer controls as well as on complex rule-based controls. EPANET was specifically developed to help water utilities maintain and improve the quality of water delivered to consumers through their distribution systems.

It can be used to design sampling programs, study disinfectant loss and by-product formation, and conduct consumer exposure assessments. It can assist in evaluating alternative strategies for improving water quality such as altering source utilization within multi-source systems, modifying pumping and tank filling/emptying schedules to reduce water age, utilizing booster disinfection stations at key locations to maintain target residuals, and planning a cost-effective program of targeted pipe cleaning and replacement. EPANET can also be used to plan and improve a system's hydraulic performance. Pipe, pump and valve placement and sizing, energy minimization, fire flow analysis, vulnerability studies, and operator training are just some of the activities that EPANET can assist with.

Top 4 Download periodically updates software information of epanet full versions from the publishers, but some information may be slightly out-of-date. Using warez version, crack, warez passwords, patches, serial numbers, registration codes, key generator, pirate key, keymaker or keygen for epanet license key is illegal. Download links are directly from our mirrors or publisher's website, epanet torrent files or shared files from free file sharing and free upload services, including Rapidshare, MegaUpload, YouSendIt, Letitbit, DropSend, MediaMax, HellShare, HotFile, FileServe, LeapFile, MyOtherDrive or MediaFire, are not allowed! Your computer will be at risk getting infected with spyware, adware, viruses, worms, trojan horses, dialers, etc while you are searching and browsing these illegal sites which distribute a so called keygen, key generator, pirate key, serial number, warez full version or crack for epanet. These infections might corrupt your computer installation or breach your privacy. Epanet keygen or key generator might contain a trojan horse opening a backdoor on your computer.

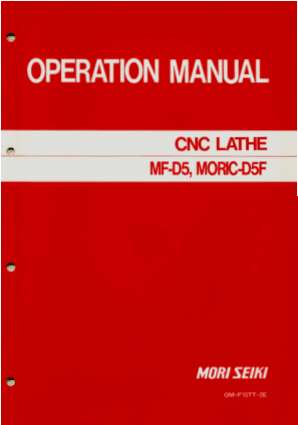

Mori Seiki 603 Operator Manual

Mori Seiki Manuals Instruction Manual and User Guide for Mori Seiki. Lyndex-Nikken Mori Seiki Live & Static Tools for SL403-603 VL553MC 2013 Catalog.

Spindle 185 mm (7.3 in.) C-type 275 mm (10.8 in.) D-type 370 mm (14.6 in.) ■ Through-spindle hole diameter Spindle type B-type −: Not applicable D-type 45/37 kW (60/50 HP) 37/30 kW (50/40 HP) 45/37 kW (60/50 HP) 45/37 kW (60/50 HP) ● ○ − − 1,500 min 1,000 min-1 700 min-1 500 min-1 -1 ○ ○ − − − ○ ● − − ○ ○ − − − − ● Turret, Feed ■ Turret indexing time ■ Rapid traverse rate 0.4 sec. X-axis: 20 m/min (787.4 ipm) Z-axis: 20 m/min (787.4 ipm) C-axis: 25 min-1 (1-station) ○: Option 37/30 kW (50/40 HP) Spindle drive motor Spindle speed. Ideal for shaft workpieces In order to achieve high-speed, high-precision machining of long workpieces, we have installed a highly rigid bed and specialized functions and equipment for bar workpieces. It is the definitive bar work machine, eliminating all compromise. In.) The travel on the cross slide may be limited depending on the size of the workpiece. 733 mm (28.8 in.) Max.

Turning diameter Max. Turning length 1,000 mm 2,000 mm (39.3 in.) (78.7 in.) 203 mm (8.0 in.) Max. Turning length ■ Tailstock travel 3,000 mm 4,000 mm (118.1 in.) (157.4 in.) Programmable tailstock SL-603/1000 1,100 mm. To improve operability when using a crane, it is equipped with a wide door opening. Depending on machining situation, the operator can slide the operation panel for ease and comfort. Operation panel travel Hydraulic steady rest The hydraulic steady rest can be set up in less time and without any manual setting thanks to automatic centering. Steady rest Bolts are tightened manually, supporting the workpiece.

Chip conveyor outside machine Chips are continuously transported out of the machine to prevent buildup inside. ● The hinge type chip conveyor is standard for the machines with distances between. Peripheral equipment System examples Robots make workpiece loading and unloading more efficient, which improves Add any Of the below options.

Consultation is required. Robot (interface). Work stocker. Workpiece holding detector Example with front and rear chucks Consultation is required By installing a large hole chuck on the front and rear ends of the spindle, it becomes possible to machine the ends of long and workpieces.

A particular advantage is seen in threading pipes. Air chuck (rear) Bar workpiece Mist collector. Coolant cooling system (separate type) Raised coolant temperature causes thermal displacement in the fixtures and workpiece, affecting the machining accuracy of the workpiece.

Use this unit to prevent the coolant from heating up. When using oil-based coolant, the coolant temperature can become extremely high even with the standard coolant pump, so please be sure to select this unit. When using oil-based coolant, please be sure to consult with our sales representative.

While this unit is not the only way to completely control the temperature of the coolant, it makes a major contribution to preventing. A New High-Performance Operating System for CNC Lathes A new high-performance operating system that pursues ease of use, and combines the best hardware in the industry with the advanced application/network systems. ▶ Outstanding operability thanks to upgraded hardware ▶ New functions for easier setup and maintenance ▶ Various types of monitoring, including internal monitoring, are possible on the screen (option) ▶ In the event of trouble, DMG MORI SEIKI’s remote maintenance service solves it smoothly MORI-NET Global Edition Advance OP Outstanding operability Vertical soft-keys Vertical soft-keys.

Location: Humble,TXRigger Needed To LoadMachines Specs Provided In Attached PDFThe scope of work performed on the Mori Seiki SL-603 is as follows:-Rebuild machine and retrofit with Fanuc CNC control-Completely disassemble machine enclosure in order to sand down damaged original paint and apply base coat and polyurethane industrial paint (Mori Seiki colors)-X ball screw to be cleaned and preloaded, replace thrust bearings-Z ball screw to be reground and rebuilt, replace thrust bearings-Headstock is completely cleaned and bearings inspected. Auction Terms & Conditions Terms and Conditions – Mohawk Machinery Liquidators 1. IDENTIFICATION: All purchasers are required to give a full name and address. Mohawk Machinery Liquidators, at its sole discretion, may deny registration to any person or entity. DEPOSIT: A Cash Deposit may be required to register if stated or may be required to continue bidding after a monetary threshold has been reached. Failure to make a required deposit may result in suspension of bidding privileges. RESERVE: All assets in the auction shall be sold to the highest bidder.

Some items may be auctioned with minimum reserve prices, and/or subject to the sellers right of confirmation. On lots with a reserve the auctioneer reserves the right to bid on behalf of the seller. Mohawk Machinery Liquidators reserves the right to reject any bid that is only a minimal increase over the previous bid. PAYMENT: All bills must be paid in full within the time announced by the auctioneer. Bills must be settled before any items are removed. NO EXCEPTIONS. REMOVAL: No lot can be removed during the sale.

All removal shall be at the expense, liability and risk of the purchaser, including disconnecting of utilities. If the purchaser does not remove an item within the announced check-out period, Mohawk Machinery Liquidators and the seller may, at their sole discretion, deem the item to have been abandoned by the purchaser and the purchaser will have no further rights with respect to the item.

Notwithstanding the foregoing, Mohawk Machinery Liquidators and the seller reserve the right to charge the purchaser for the costs of storage beyond the checkout period, and/or such said items may be resold at public or private sale, without notice, with all deficiencies and expenses charged to the defaulting purchaser. PAYMENT: Mohawk Machinery Liquidators accepts the following methods of payment: cash, cashiers check, money orders or wire transfers. Personal and Business Check are accepted, however Mohawk Machinery Liquidators reserves the right to require a bank Letter of Guarantee, Guaranteeing Payment in Full, without condition upon Demand.

Credit Card purchases over $1000.00 are subject to a 3% handling charge. A $35.00 handling charge may be added to the purchase price of all titled vehicles. CONDITION OF LOTS: Bidders shall examine or inspect items prior to the day of the auction. ALL ITEMS ARE SOLD AS IS, WHERE IS AND WITH ALL FAULTS. NEITHER SELLER NOR MOHAWK MACHINERY LIQUIDATORS MAKES ANY WARRANTY, EXPRESS OR IMPLIED, AS TO THE NATURE, QUALITY, VALUE OR CONDITION OF ANY ASSET. Mohawk Machinery Liquidators AND SELLER EXPRESSLY DISCLAIM ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No allowance will be made for errors in cataloging, genuineness, defects, or imperfections not noted. INDEMNIFICATION: Purchaser agrees to indemnify and hold harmless both Owner and MOHAWK MACHINERY LIQUIDATORS from and against all claims and liabilities resulting from assets sold, including but not limited to: proximate or consequential damages, failure to comply with local, state or federal laws, and cost or legal expenses arising there from. CLAIMS: No claims will be allowed after the said item has been removed from the premises. NON-DELIVERY: Neither owner or MOHAWK MACHINERY LIQUIDATORS shall be liable for non-delivery to any purchaser of any lot, other than for the return to the purchaser the sum paid on said lots should the purchaser be entitled thereto. COMPLIANCE WITH TERMS: By obtaining a bidding number, each bidder represents and irrefutably warrants they shall not misrepresent their ability to close the transaction pursuant to the terms and conditions of sale.

Any bid they make on an item constitutes an irrevocable offer to buy the item for the full amount of the bid. If bidder fails to make payment of bills in full, by the specified time, the auctioneer may retain all monies received as deposits or otherwise as liquidation damages. Immediate notification is required if a mistake is made in bidding, Buyer may still be held responsible for the bid.

DANGEROUS AUCTION SITE: Bidders acknowledge that an auction site is a potentially dangerous place. Every person enters the auction site at his or her own risk with notice of the condition of the premises and the activities that will be or have been conducted on the premises. Persons attending during preview, sale or removal assume all risks of injury, damage or loss of property and specifically release the auctioneer from liability. ADDITIONS OR WITHDRAWALS: Mohawk Machinery Liquidators may, in its discretion, offer the assets for sale by the piece or by the lot, or in any manner that best serves the interest of the seller.

The seller has the right to add assets before the bidding, or remove assets from the auction either before or after bidding has been completed. In the event of a removal after bidding has been completed, the purchasers sole remedy shall be the refund of any purchase price actually paid 14. FALSE BIDS: If the high bidder fails to complete the transaction Mohawk Machinery Liquidators reserves the right to dispose of the asset in the best interests of the seller. Any High Bidder that fails to complete a transaction will be held responsible for all damages resulting from that action. RECORD: The record kept by Mohawk Machinery Liquidators will be taken as final in the event of any dispute.

AGENCY: Mohawk Machinery Liquidators is acting only as an agent and is not responsible for the actions of the principals. EXPORT: Purchaser agrees to comply with all applicable US export laws, and acknowledge that Mohawk Machinery Liquidators is not the exporter of any items. Certain items offered at the auction may constitute Restricted Technology. Under federal law, such items cannot be shipped outside of the United States. Mohawk Machinery Liquidators makes no representation or warranty concerning, and has conducted no investigation to ascertain which items, if any, constitute Restricted Technology. MISPRINTS: Mohawk Machinery Liquidators relies on information about assets in the auction provided by the seller and undertakes no investigation of that information. Mohawk Machinery Liquidators shall not be responsible for the correct description, genuineness, authenticity of, or defect in any lot, and makes no warranty therewith.

Mohawk Machinery Liquidators will announce any additions to or deletions from the catalog on the day of the auction. The auctioneer assumes no responsibility for, and makes no representations or warranties concerning, descriptions of assets contained in marketing materials for the auction. It is the bidders obligation to verify such descriptions prior to the auction. COSTS OF COLLECTION. Mohawk Machinery Liquidators shall be entitled to collect all damages, costs and expenses incurred in connection with collection of any amounts owed to MOHAWK MACHINERY LIQUIDATORS by Purchaser, including without limitation any attorneys’ fees. Purchaser agrees that the purchase from Mohawk Machinery Liquidators occurs in Ohio. Any disputes between Mohawk Machinery Liquidators and Purchaser shall be governed by the laws of the State of Ohio without regard to the provisions thereof which concern conflicts of laws.

Purchaser agrees that any controversy arising between the Purchaser and Mohawk Machinery Liquidators shall be litigated exclusively in Ohio. The state and federal courts and authorities with jurisdiction in Ohio shall have exclusive jurisdiction over all controversies which shall arise between Mohawk Machinery Liquidators and Purchaser.

Purchaser irrevocably consents to service, jurisdiction, and venue of such courts for any such litigation and waives any other venue to which it might be entitled by virtue of domicile, residence or otherwise. WAIVER OF JURY TRIAL.

Purchaser hereby knowingly, voluntarily, and irrevocably waives any and all right to a trial by jury in any legal proceeding arising out of or relating to these terms. ENTIRE AGREEMENT. These Terms and Conditions contain the entire understanding of the parties hereto with respect to the subject matter addressed herein and supersede all prior agreements, discussions, negotiations and understandings between the parties hereto with respect to such subject matter.

CONTRACT MOVERS: Any type of outside contractors, including riggers and machinery movers, will not be allowed to work on the auction premises until they have provided Mohawk Machinery Liquidators proper insurance, protecting Mohawk Machinery Liquidators, the seller and the landlord from all and any claims resulting from their actions. ADDITIONAL AUCTION TERMS may be posted within the Mohawk Machinery Liquidators Website or send via email to active bidders. MALFUNCTION: ANY Malfunction, Shutdown or Temporary loss of Service involving bidding for Items may render the results of the auction Void.

In such an event Mohawk Machinery Liquidators reserves the right to remedy the situation in whatever way best represents the seller, including canceling the existing bids. CREDIT CARD INFORMATION: Mohawk Machinery Liquidators reserves the right to charge your credit card for the full amount of your winning lot(s) plus any applicable sales tax and/or Buyers Premium if you have not made payment to Mohawk Machinery Liquidators on or before the final day of the auction checkout. Credit Card purchases over $1000.00 are subject to a handling charge.

SALES TAX – All sales are subject to state and local taxes, unless a proper exemption certificate including tax exempt number is presented at the time of payment. Sebae Data Solutions, Inc. SERVICE TERMS AND CONDITIONS ACCEPTANCE OF TERMS Sebae Data Solutions, (the makers of Auction Flex & HiBid (formerly Bidopia) hereafter referred to as 'Sebae'), provides its service to you, subject to the following Terms & Conditions ('TAC'), which we may update from time to time without notice to you. The most current version of the TAC can be found found at any time by visiting the link: USE AND REGISTRATION Our services are available only to, and may only be used by individuals who can form legally binding contracts under applicable law. Without limiting the foregoing, our services are not available to children (persons under the age of 18) or to temporarily or indefinitely suspended members. If you are under the age of 18, you can use this service only in conjunction with, and under the supervision of your parents or guardians. If you do not qualify, please do not use our service.

Mori Seiki 603 Operator Manual Pdf

If you are registering as a business entity, you represent that you have the authority to bind the entity to the TAC. REGISTRATION OBLIGATIONS In consideration of your use of the Service, you agree to: (a) provide true, accurate, current and complete information about yourself as prompted by the Service's registration form (such information being the 'Bidder Information') and (b) maintain and promptly update the Registration Data to keep it true, accurate, current and complete. If you provide any information that is untrue, inaccurate, not current or incomplete, or Sebae has reasonable grounds to suspect that such information is untrue, inaccurate, not current or incomplete, Sebae has the right to suspend or terminate your account and refuse any and all current or future use of the Service (or any portion thereof). DESCRIPTIONS OF SERVICE Sebae provides the following services under the Auction Flex & HiBid trademarks: Integrated Web Service (for auctioneers), internet bidding (absentee, online-only, & webcast).

You can learn more about these services in the following sections. HIBID INTERNET AUCTION PLATFORM & WEB SERVICE DESCRIPTION Sebae provides the HiBid (formerly Bidopia) Internet Auction Platform & Web Service ('HWS') under the HiBid trademark as a software solution for auctioneers wishing to extend the audience of their live auctions to the internet. The HWS provides various features including internet absentee bidding, internet-only auctions, and webcast auctions. The HWS is able to changes its appearance to coincide with the website that it is powering. Accordingly, the HWS powers the www.hibid.com website as well as numerous Auction Flex customer websites. This ability to change appearance is a feature of the HWS.

Much like internet merchant account providers can host a secure web page for a vendor to easily process payments, the HWS hosts certain portions of the auctioneer's website to easily enable advanced features such as internet bidding. INTERNET ABSENTEE BIDDING Internet absentee bidding allows you to place a bid for an item in advance of an auction. This allows you to place bids on lots without actually attending the auction. INTERNET-ONLY AUCTIONS Internet only bidding allows you to place a bid for an item prior to the auction lot closing online. In an internet-only auction there is no live auction. WEBCAST AUCTIONS Webcast auctions allow you to bid in real-time against other bidders or place pre-bids prior to a lot going 'live'. Lots are sold in accordance with the Auctioneer's terms and conditions which are accessible from each lot's page.

It is your responsibility to read and accept the Auctioneer's terms and conditions prior to placing your bid. When you place a bid you are agreeing to be bound by the Auctioneer's & Sebae's terms and conditions. By placing a bid you are entering into a legally binding and enforceable contract. Please keep in mind that you are bidding against other internet bidders as well as floor bidders, phone bidders, and regular absentee bidders (this list does not constitute a complete list of bidder types but does highlight the common bidder channels). The auctioneer, at their discretion, can approve or deny bidders. The auctioneer reserves the right to accept or deny bidders for any reason.

Prior to approval the auctioneer may contact you to determine your credit worthiness. If the auctioneer approves your bid, the auctioneer will then process your bid in accordance with their terms and conditions.

Should your bid for a lot prove successful, the auctioneer may contact you to arrange for payment & shipping (if applicable). If the auctioneer required registration via a credit card, the auctioneer reserves the right to process your winning bids to the credit card provided during registration. Sebae, through the Auction Flex & HiBid products & services, facilitates the internet bidding process between the Auctioneer & the bidder. Sebae is in no way a party to the transaction. Because Sebae is not a party to the transaction, you accept that you will have no claim or cause of action against Sebae in respect of the sale (or non-sale) of any Lot. If you have a dispute with an Auctioneer or another user of the Service with regard to the sale (or non-sale) of any Lot you agree that Sebae, its officers, agents, employees will not be liable for losses (including, but not limited to, loss of profits, special loss, indirect loss and consequential los), costs, damages, liabilities, claims, demands and expenses of any kind arising out of or connected with such dispute.

You also accept that none of the aforementioned are under any obligation to take any action to resolve any dispute between you and an Auctioneer Sebae is not responsible for any typographical, pictorial or technical errors in information about Lots on the Site as provided by Auctioneers. Sebae does not evaluate Lots and does not act as a specialist or expert on any related subject matter. Sebae makes no warranties or representation of any kind or nature with respect to Lots (including but not limited to representations or warranties as to the accuracy of description, genuineness, quality, authorship, attribution, provenance, period, culture, source, origin or safety). If you have any questions, e-mail the Auctioneer directly.

In particular, make sure that you understand the Auctioneer's payment terms and shipping terms. BIDDING The Service requires you to login with your username and password prior to placing a bid on a Lot. Making bids with false information or with stolen credit card information is prohibited and illegal. Your user name and password are required in order to place internet bids. Making bids in a false name or with an invalid or stolen credit card is prohibited.

Each bid carries the computer coding of the Internet provider which allows the individual user to be traced and Sebae may at its discretion release this information to enable legal action to be taken. Sebae may, in its entire discretion, refuse or remove bids where it suspects that bids contravene this prohibition. By placing a bid, you are making a binding and irrevocable offer to purchase the Item at any price up to the maximum bid amount you submit. If you win, you must complete the transaction, subject to any contractual right or other right at law to rescind the contract in certain circumstances. Failure to complete transaction without lawful reason is not only a breach of your contract with the Seller but also a breach of this User Agreement. The amount bid can be increased but cannot be decreased.

The auctioneer may, at their discretion, allow you to withdraw and resubmit a bid in the case of bids containing an obvious typographical error. You may forward a request to withdraw a bid and resubmit a correct bid by immediately sending an email to the auctioneer, however, there is no guarantee that any bid will be withdrawn. Although Sebae will use best efforts to forward all bids, Sebae does not accept any responsibility for lost bids or problems with the recipient auctioneer's ability to process your bid.

Moreover, Sebae cannot guarantee that bids received will be processed by the individual auctioneers. Please note that Sebae's role is limited to the provision of the Site for dissemination and publication of information provided by the Sellers. THE WINNING BID The winning bid in an auction will be the highest bid that exceeds any reserve (if a reserve exists). In the case of equal bids, the earliest bid received will be the winning bid. If a higher bid is subsequently withdrawn or removed then the auctioneer shall have the right to accept the next highest bid. NOTICE OF END OF SALE, PAYMENT & SHIPPING After the sale has ended, the auctioneer will notify the winning bidder via phone, fax or mail that they have won. If you do not receive notice that you have made the winning bid and think that you are the top bidder, you should check with the auctioneer directly.

You will make all payment for Items to the auctioneer in accordance with their terms and conditions. BUYER'S PREMIUM, TAXES AND DUTIES If you are a successful bidder, you are responsible for paying any buyer's premium, taxes and duties (including any VAT, sales tax and import duties) that may be imposed on the final price paid for an Item. Accordingly, it is your responsibility to check the applicable taxes and duties that may be imposed on an Item prior to bidding for it.

PRIVACY We do not sell or rent your personal information to third parties for their marketing purposes without your explicit consent and we only use your information as described in the Privacy Policy. COPYRIGHT All material and content as provided by the Service is protected by copyright and similar rights. You can not use or make available any of that material for any commercial purpose.

SPECIAL ADMONITIONS FOR INTERNATIONAL USE Recognizing the global nature of the Internet, you agree to comply with all local rules regarding online conduct and acceptable content. Specifically, you agree to comply with all applicable laws regarding the transmission of technical data exported from the United States or the country in which you reside. DISCLAIMER OF WARRANTIES You expressly understand and agree that: a. Your use of the service is at your sole risk. The service is provided on an 'as is' and 'as available' basis. Sebae expressly disclaims all warranties of any kind, whether express or implied, including, but not limited to the implied warranties of merchantability, fitness for a particular purpose and non-infringement.

Sebae makes no warranty that (i) the service will meet your requirements, (ii) the service will be uninterrupted, timely, secure, or error-free, (iii) the results that may be obtained from the use of the service will be accurate or reliable, (iv) the quality of any products, services, information, or other material purchased or obtained by you through the service will meet your expectations, and (v) any errors in the software will be corrected. Any material downloaded or otherwise obtained through the use of the service is done at your own discretion and risk and that you will be solely responsible for any damage to your computer system or loss of data that results from the download of any such material. No advice or information, whether oral or written, obtained by you from Sebae or through or from the service shall create any warranty not expressly state in the TAC. Email Privacy Policy We have created this email privacy policy to demonstrate our firm commitment to your privacy and the protection of your information. Why did you receive an email from us? If you received a mailing from us, (a) your email address is either listed with us as someone who has expressly shared this address for the purpose of receiving information in the future ('opt-in'), or (b) you have registered or purchased or otherwise have an existing relationship with us.

Mori Seiki 603

We respect your time and attention by controlling the frequency of our mailings. How we protect your privacy We use security measures to protect against the loss, misuse and alteration of data used by our system. Sharing and Usage We will never share, sell, or rent individual personal information with anyone without your advance permission or unless ordered by a court of law. Information submitted to us is only available to employees managing this information for purposes of contacting you or sending you emails based on your request for information and to contracted service providers for purposes of providing services relating to our communications with you.

Bio Study Guide Answers

The Cell The cell is possibly the most important concept in biology since it is the basic unit of life. Every living organism is made up of cells (or just one in the case of bacteria). Your body is composed of microsopic cells that are only visible if viewed under a microsocope. All the animals, trees and plants are made up of cells that share many similar characteristics. They all have s separating them from the outside environment, DNA to store information, RNA to pass this information to the ribosome- and ultimately protein that is translated from the RNA. The, or plasma membrane separates the cell from exterior environment and is composed of a phospholipid bilayer. It is composed of phospholipids which each have a polar (hydrophillic) head and a polar (hydrophobic tail).

The polarity of the phospholipids helps them self assemble into a structure where the hydrophobic tails all face inward away from the aqueous interior and exterior of the cell. Cell membrane' title='The Phospholipids of the Cell Membrane' The is embeded with proteins. Transmembrane proteins pass all the way through the membrane, while peripheral proteins only pass through one side of the bilayer. Transmembrane proteins are often are involved in the transport of compounds and nutritents across the lipid bilayer since only small hydrophobic molecules, water and gas can diffuse freely through the hydrophobic interior.

Organelles of the Cell Eukaryotic cells (all organisms except bacteria and archaea (prokaryotes)) have complex organelles which are surrouned by their own membrane (similar to the ). Nucleus - the nucleus is where DNA is stored and where RNA transcription occurs. Each cell has one nucleus. Within the nucleus is a structure called the nucleolus which is the site of ribosome assembly. The image below is an image of a cell with the nucleus stained blue and the multiple mitochondria stained red Mitochondria - often refered to as the 'powerhouse' of the cell, this is the organelle that generates ATP (the energy currency of the cell).

Biology ANSWER KEY Unit 1 – Introduction to Biology STUDY GUIDE Essential Skills Questions: 1-1. Be able to identify and explain the 5 characteristics of living things.

Mitochondria have a highly folded inner membrane that provides surface area for the enzymatic reactions that produce ATP. The interior of the two membranes is called the matrix, the space in between the two membranes is called the intermembrane space and the folds created by the inner membrane are called cristae. Mitochondria also contain their own DNA which encodes some of the enzymes that are used inside the mitochondria. Endoplasmic reticulum - the system of membranes used for the folding and transport of proteins.

Bio 8.7 Study Guide Answers

Rough ER (endoplasmic reticulum) is covered by ribosomes while Smooth ER is not. Ribosomes are structures made of protein and rRNA (ribosomal RNA) where proteins are made (translated). Golgi apparatus - used for modifying and packaging of proteins Chloroplast - in plants this organelle is responsible for the reactions of photosynthesis Cell Parts There are other important components of the cell that are not considered organelles since they are not surrounded by their own lipid bilayer. Ribosomes - the ribosome is a large complex made of RNA and protein that translates mRNA into protein. Lysosomes - where the breakdown of nutrients can occur using enzymes Cell Membrane - this is the structure composed of a lipid bilayer that separates the cell from the outside environment Cell Wall - found only in plant and bacteria this structure is found outside the and serves as a more rigid protective barrier Differences Between Eukaryotes and Prokaryotes Bacteria (and archaea which are seldomly mentioned) are prokaryotes. The term prokaryotes is derived from pro (before) and karya (nucleus): before-nucleus = pro-karya = prokaryote. This is because it is thought that bacteria are still very similar to their primitive ancestors which did not have a nucleus.

So- bacteria (prokaryotes) do not have a nucleus, while all eukaryotic cells do have a nucleus (this is a popular question for exams- and a common mistake). Bacteria also lack all other membrane bound organelles. Bacteria do not have: organelles nucleus mitochondria endoplasmic reticulum golgi appartus chloroplast lysosomes Bacteria do have: ribosomes cell wall (which eukaryotes don't have) Its also important to remember that while bacteria don't have a nucleus they definitely still have DNA organized in a chromosome that is transcribed to mRNA and then translated to protein on a ribosome. Download the free study guide.